Have you ever run a solid load separation only to find your peaks are broad and your resolution poor—despite doing everything “right"? The culprit might be hiding in your solvent line.

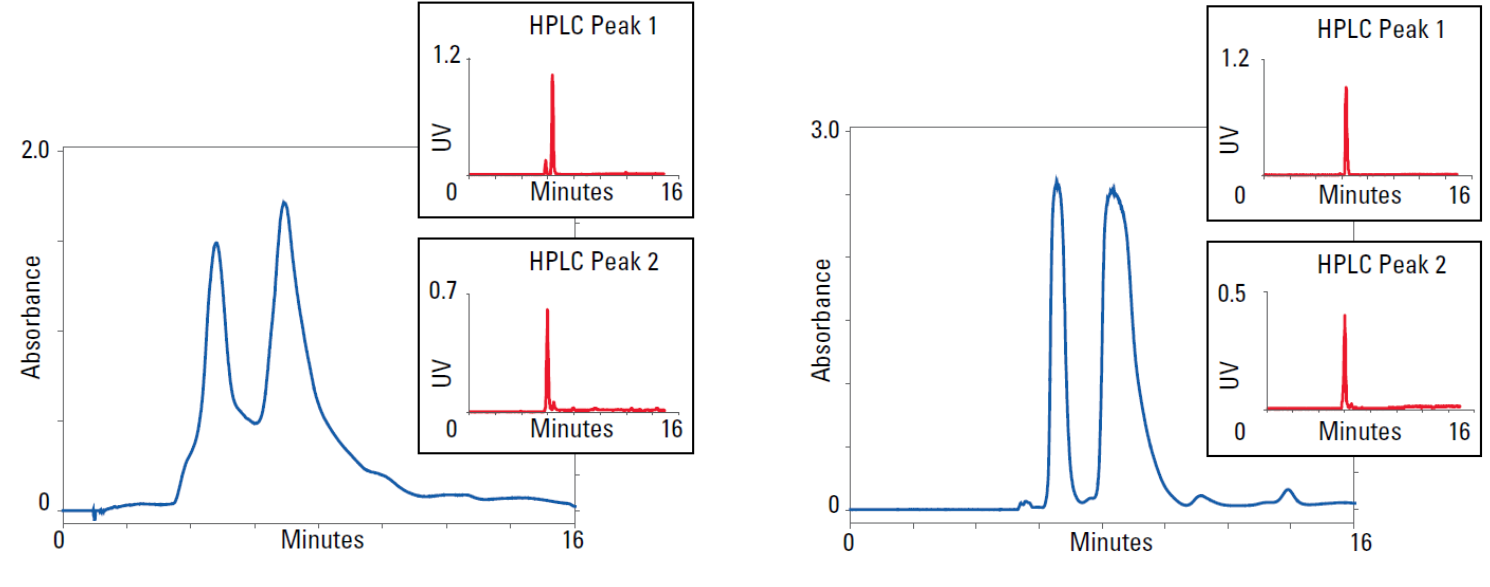

Solid sample loading is an effective technique for improving resolution and increasing sample loading capacity. However, if the sample is not thoroughly dried onto the adsorbent material, chromatographic performance can suffer (Figure 1). This is due to residual amounts of the strong solvent—used to dissolve the sample—remaining in the solid load cartridge. Even trace amounts of strong solvent can cause premature elution and broadened peaks.

Figure 1: Separation of two compounds using solid loading. Left: Sample was not completely dried onto the adsorbent material, resulting in band broadening and poor resolution. Right: Sample was fully dried, yielding baseline resolution and sharp peak shape.

Figure 1: Separation of two compounds using solid loading. Left: Sample was not completely dried onto the adsorbent material, resulting in band broadening and poor resolution. Right: Sample was fully dried, yielding baseline resolution and sharp peak shape.

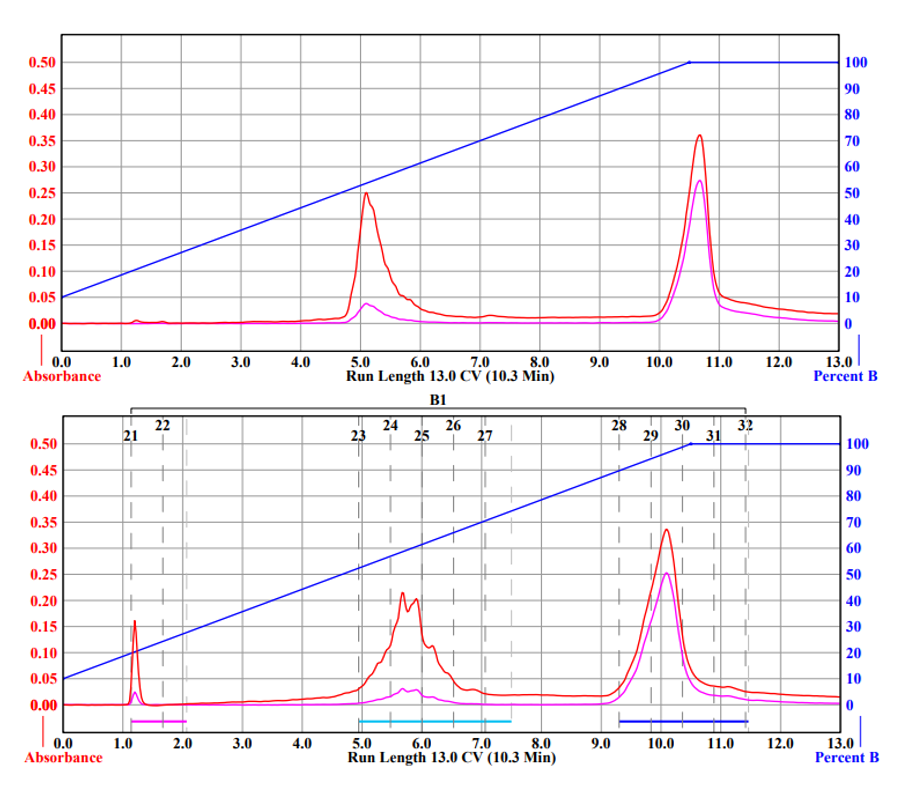

Similar issues can arise during consecutive solid load separations. In these cases, the problem isn't incomplete drying, but the inadvertent introduction of 100 percent solvent B at the start of the next run. Many methods end at 100 percent solvent B to ensure complete elution of all compounds. While the column is typically equilibrated before the next injection, the line feeding into the top of the solid load cartridge often retains the last solvent pumped—100 percent B. This residual strong solvent can prematurely elute the sample and degrade resolution.

To prevent this, air-purging the solid sample line before each separation is recommended. On a Teledyne LABS

NextGen system, navigate to

Tools >

Manual Control > and select

Air Purge Cartridge to perform the purge.

Figure 2: Separation of Fast Green FCF and Erythrosine on a RediSep Gold C18 column. Solvent A: H₂O with 0.1% FA. Solvent B: MeOH with 0.1% FA. Top: Solid load line was air purged prior to separation. Bottom: solid load line was not air purged prior to separation.

Figure 2: Separation of Fast Green FCF and Erythrosine on a RediSep Gold C18 column. Solvent A: H₂O with 0.1% FA. Solvent B: MeOH with 0.1% FA. Top: Solid load line was air purged prior to separation. Bottom: solid load line was not air purged prior to separation.

In the bottom of Figure 2, Fast Green FCF begins eluting at 1 column volume (CV) driven by the residual strong solvent. This also contributes to band broadening in both dyes. In contrast, the top chromatogram in Figure 2 shows sharper peaks and improved resolution, thanks to air-purging the solid load line.

If you're seeing unexpected peak shapes or poor resolution in your solid load separations, try air-purging your sample line before each run. It's a simple fix that can dramatically improve your results.

About Dylan Cavey, Applications Chemist, Teledyne LABS

Dylan assists the Teledyne LABS engineering department in research and development of chromatography instruments; provides customer training, method development and application support; and installs instruments at customer sites. Earlier, he was a biochemist and created a DNA purification device. Dylan is adept in flash, SFC and HPLC chromatography, mass spectrometry and related methods and technologies. He earned his bachelor's degree in biochemistry from Adams State University.